Driving Innovation with 3D Printing: M. Holland & Eaton

By Carlos Aponte, Market Manager, 3D Printing

At M. Holland, we work closely with customers to understand their goals and challenges and find the right solutions. Eaton, an international power management company, is collaborating with us to increase the adoption of additive manufacturing and easily scale production across its locations worldwide. Eaton manufactures products for the electrical, hydraulic and mechanical power industries in over 175 countries. The company has a robust approach to research and development focused on sustainable, innovative technologies like additive manufacturing. Eaton worked with M. Holland to produce complex, high-performance components using 3D printing. Together, we have explored how the additive manufacturing process can be faster and more sustainable compared to traditional manufacturing, which will ultimately help support Eaton and its business goals.

How Eaton Prioritized 3D Printing

In 2016, Eaton opened its Additive Manufacturing Center of Excellence (AM CoE) in Southfield, Michigan. The facility serves as a hub to train its engineers, develop 3D printing techniques and facilitate the adoption of additive manufacturing throughout the organization.

“We see additive manufacturing technology as a growing opportunity that will continue to strengthen Eaton’s competitive advantage to deliver cost, performance and lead time benefits to our customers,” said Cameron Peahl, Additive Manufacturing Manager at Eaton. “It’s why we’ve prioritized 3D printing innovation and will continue building our relationship with M. Holland.”

Today, the AM CoE offers more than just training. It also serves as a low-rate initial production facility for metal and polymeric 3D printing applications, improving Eaton’s speed to market and sustainable manufacturing efforts in the electrical, aerospace, hydraulic and automotive industries.

Innovation and Implementation

M. Holland began its relationship with Eaton in 2018, providing pellets for production, printing ad hoc parts, placing 3D printers, and providing “lunch and learn” training sessions for Eaton employees. After working with many different Eaton locations independently, M. Holland and Eaton transformed their relationship into a collaborative agreement. This allowed M. Holland’s 3D Printing team to collaborate with Eaton on 3D printing application development and implement a formalized training program for Eaton’s engineers. In addition, M. Holland provided materials, design and testing services, as well as overflow production support.

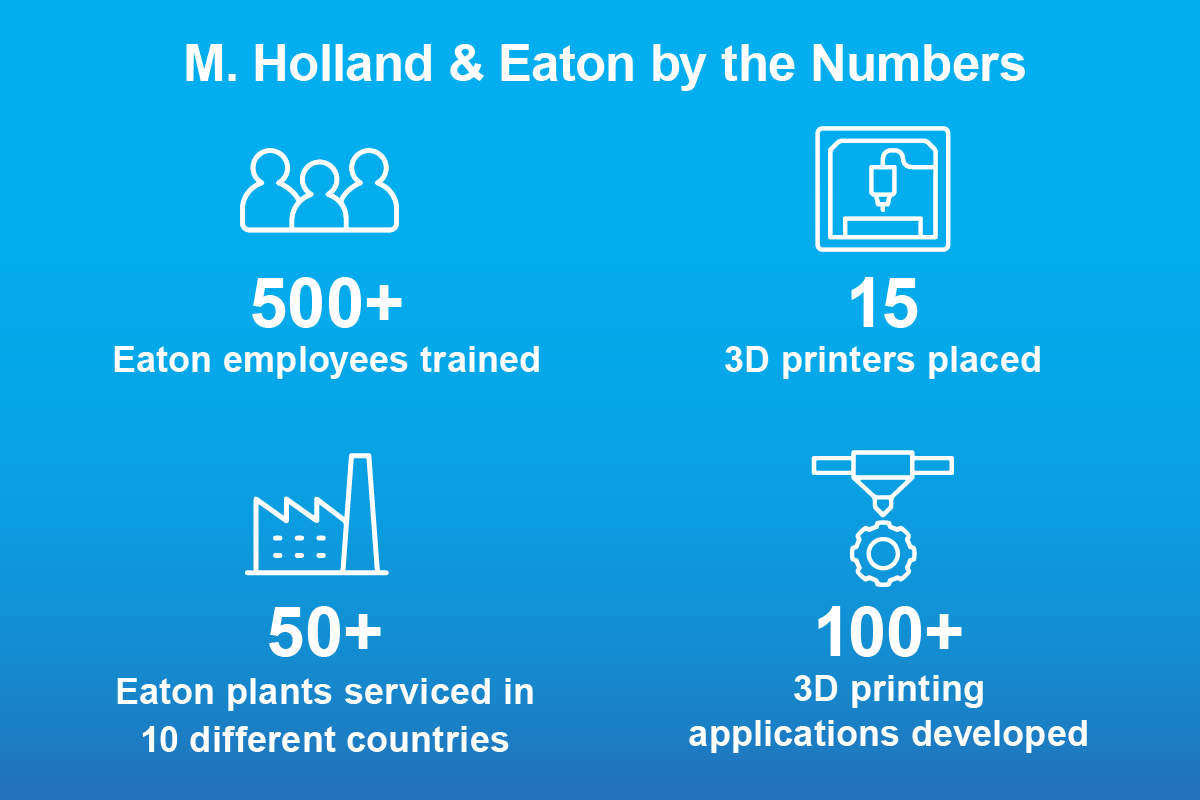

M. Holland got to know Eaton’s physical manufacturing processes and recommended opportunities for Eaton to integrate additive manufacturing into its operations. Together, we have already discovered over 100 applications for 3D printing across Eaton’s business, including in the aerospace, electrical and vehicles segments.

Continuing Education in Additive Manufacturing

Eaton continued to work with M. Holland to develop a training program for its engineers. The program gives Eaton’s engineers the tools they need to implement additive manufacturing at their respective plants. An introductory training covers the basics of 3D printing, including an overview of different processes and applications, common adoption challenges, optimizing return on investment, and information about the relationship with M. Holland . Additional learning opportunities include design for additive manufacturing, hands-on operator training and advanced application analysis.

Measurable Results

Our collaboration began with a discovery meeting and subsequent training sessions at the AM CoE but has evolved to meet the needs of individual plants. We have now trained over 500 Eaton employees and serviced over 35 plants globally. As of 2022, M. Holland has helped Eaton place 15 new 3D printers across the organization’s facilities. And in 2023, we’re expanding our training catalog to better meet Eaton’s specific needs.

“We’ve reached a point with Eaton where collaborating with multiple business units has allowed us to learn more about their operations, building our knowledge base to better tailor our offerings,” said Allison Rickman, Strategic Account Manager, 3D Printing. “We’ve established the basics, and now we’re expanding into really customized, industry-specific areas to meet Eaton’s needs.”

From application development and machinery recommendations to training and part design, M. Holland has the right combination of experience to help bring your 3D printing vision to life. Learn more about our additive manufacturing capabilities or visit our market page.

Related Content:

- M. Holland’s 2023 Plastics Industry Trends & Predictions

- 2023 Market Insights: 3D Printing, Color & Compounding and Rotational Molding

- 2023 Market Insights: Healthcare, Packaging and Sustainability

- 2023 Market Insights: Automotive, Electrical & Electronics and Wire & Cable

- M. Holland Company Restructures Leadership Team to Support Growth

- M. Holland’s 3D Printing Group Expands Portfolio of Braskem PE and PP Filament

- M. Holland’s 3D Printing Group Expands with New Materials and Supply Partners

- M. Holland Launches New 3D Printing E-Commerce Website